Hosokawa Solids

We set the standards in bulk solids handlingHosokawa Solids belongs to the Hosokawa Alpine Group and is therefore a part of the Hosokawa Micron Group. The company was founded in 1969 and brings with it more than 50 years of experience in bulk solids handling technology. Hosokawa Solids provides its own developed process solutions and systems in the core competences of storage, conveying, dosing and weighing technology. We set the standards when it comes to bulk solids handling as well as global and integrated automation. With facilities for development, manufacturing and testing in Germany and Spain, the three business units of Components, Equipment and Service as well as special design lines, Hosokawa Solids supplies complete solutions to the food, cosmetics, chemical, mineral, environmental, rubber and plastics industries. More information about the Solids Solutions Group

Since January 2020, the former solids solutions Group has been part of the Hosokawa Alpine Group. This means that customers now receive complete solutions from a single source in the areas of mechanical process engineering and bulk solids handling.

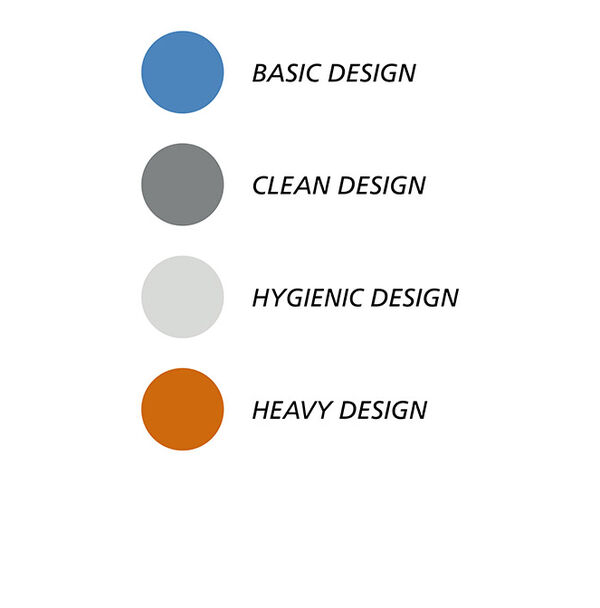

Hosokawa Solids Design Lines

Product characteristics and operating conditions require different equipment designs. The following design lines are available for this purpose.

- Solids Basic Design for dry processes with non-corrosive bulk solids of low to medium hardness

- Solids Clean Design for processes with aggressive media and those that must be free of iron oxide or ferritic particles

- Solids Hygienic Design Dry is used for dry processes with dry cleaning. It is designed for food & cosmetic products

- Solids Hygienic Design Wet is used for wet processes and dry processes with wet cleaning. It is designed for food & cosmetic products

- Solids Heavy Design for abrasive bulk solids as well as corrosive bulk solids and/or higher temperature processes

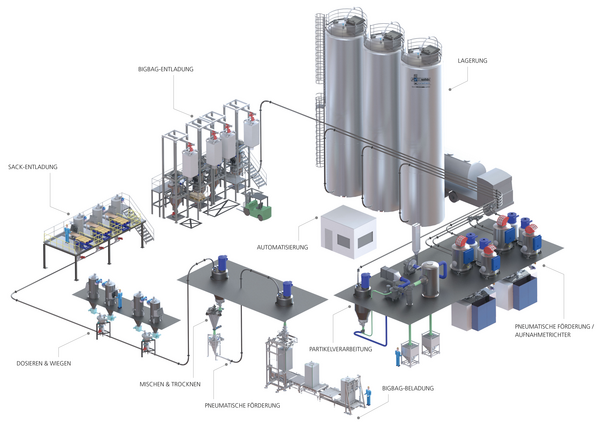

Hosokawa Solids provides systems in the core competences of storage, conveying, dosing and weighing technology. These are integrated into an optimised overall solution for the customer and continuously adapted to the product characteristics and operating conditions of various industries.

For your individual requirements and needs:

- Identifying the task and objective

- Examining raw materials and intermediate products for material properties and flow behaviour

- Developing a concept for complete process solutions

- Engineering entirely with process engineering, apparatus technology and automation

- Manufacturing and delivering all equipment

- mechanical and electrical assembly, commissioning, training and supervising operating personnel

- Full service around the clock

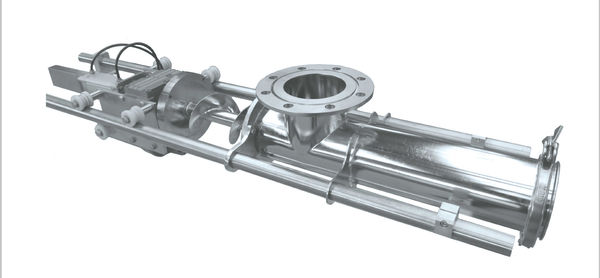

Components

Innovative, specialised and customisedFrom discharging devices to dosing equipment: The components from Hosokawa Solids are manufactured by a highly qualified and experienced team. In addition, Hosokawa Solids offers adapted processes and homologations for your specific industry and design line.

- Hygienic designs according to EHEDG guidelines

- Manufacture of pressure vessels according to AD 2000-Merkblatt HP 0 Filling equipment: Trucks, wagons

- Certified according to ATEX Directive 2014/34/EU

Service

Comprehensive, modular, efficientWith the system-specific service from Hosokawa Solids, you can always feel rest assured. You decide for yourself to what extent and how often you want to use our service package for hardware modernisation and maintenance.

Solids after-sales service:

- Spare parts and repairs: high availability of original parts, minimum downtime for maximum productivity

- Process control: Consulting and optimisation services, especially for older machines

- Remote services: fast assistance in the case of system defects and reduction of service costs

Testing facilities for bulk solids

Due to the large number of industrially produced bulk solids and their diverse properties, further investigations or bulk solids tests are often necessary to ensure the reliable design of plants, building upon the extensive experience gained from previously built plants. For this purpose, Hosokawa Solids has two testing facilities in Landsberg am Lech (Germany) and Zarautz (Spain).

Industrial-scale tests can also be carried out in these facilities for complex tasks. The tests required for the further development of processes, devices and components also take place at these locations. A wide range of testing facilities are available for our core competencies.

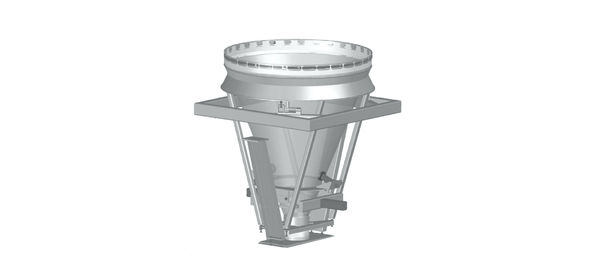

Storage and discharge

- Investigation of time consolidation during storage in silos and containers

- Extra-VIB discharge system

Pneumatic conveying

- Feeding via transport containers in different sizes

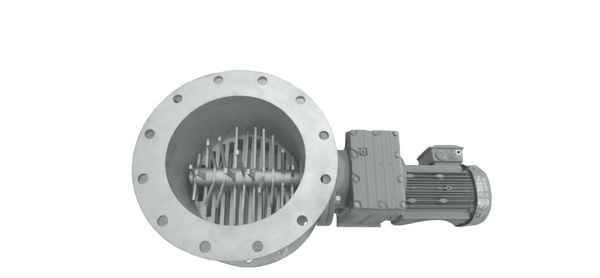

- Feed via rotary valves

- Conveying distances of up to 180 m

- Plug flow conveying with bypass in pressure or suction mode

- Dense phase pressure conveying or vacuum operation

- Dilute phase conveying

Weighing and dosing

- Dosing and transfer system VACU FILL

- weighed sending and receiving containers

- Dosing screws

- Dosing rotary valves

Our extensive testing facilities not only allow us to lay the foundations for the safe design of your system, but we can also support you with investigations into the feasibility of new production methods or in the optimisation of your production processes. Get in touch with us!

Engineering service

The engineering service is a part of the service package from Hosokawa Solids that offers you the following options:

- Basic engineering and detail engineering

- Commissioning and measurements

- Problem analysis on site

- Measurement on site

- Security analysis

- Explosion protection document (cooperation with TÜV)

- Process engineering and static calculations

- Process engineering design

- Apparatus engineering design

- Electrical planning and programming

- Three-dimensional layout planning

- Economic review

- Atex consulting

Plant engineering

Hosokawa Solids provides you with extensive know-how regarding storing, discharging, conveying, dosing and weighing bulk solids and in the automation of these processes. Based on our own technologies, equipment and components, we plan, supply and build complete bulk solid installations in a number of application areas according to your requirements to solve your specific task. More than 45 engineers and technicians guarantee the competent, precise and timely realisation of your project:

Project definition and basic engineering

- Taking over the task

- Investigations in laboratory and testing facilities

- Elaboration of the process diagram

- Selection and sizing of components

- Preliminary arrangement planning

Detail engineering and execution of the order

- Elaboration of the P+I diagram

- Engineering the control and instrumentation

- Planning the arrangement and piping

- Procurement and production

- Quality assurance and documentation

Installation and commissioning

- Shipping

- Installation on site

- Cold test of the system

- Commissioning with the product

- Proof of performance and trial operation

Since 1969, we have built well over 1,000 systems for a wide variety of bulk solids to the full satisfaction of our customers. You can find plenty of examples under Applications and Sector Solutions. We’ll take on your challenge!

About us

Your bulk solids. Our solution.Solids, founded in 1969 by H. J. Linder in Landsberg am Lech (Germany) and in the Spanish Basque Country, and has over 50 years of experience in the field of bulk handling technology. The company initially advised customers on the project planning and execution of automatic bulk solids systems (System Technik). Since 1983, it has also been producing its own machinery and equipment for handling bulk solids at its site (Components Migsa). Its portfolio also includes special designs, after-sales service, inspections, maintenance and repair.

Since January 2020, Solids has been part of the Hosokawa Alpine Group and is now part of the Hosokawa Micron Group as Hosokawa Solids.

Since 2021, the locations of Hosokawa Solids Mexico and Hosokawa Solids Chile have strengthened the expert network in Latin America. Besides, Solids counts on sales and service offices worldwide.

Hosokawa Solids is your competent partner for a wide variety of bulk solids productions and bulk solids processing industries, providing its own developed process solutions and equipment. The company’s core competencies lie in technologies such as storage & discharge, pneumatic conveying, weighing & dosing as well as integrated control and automation, complemented by a comprehensive, modular and efficient service.

Based on these competencies, the company offers overall and turnkey industry solutions for chemicals, food & beverages, animal feed, minerals, plastics & rubber, energy and environment.

Hosokawa Solids Spain has around 7000 m2 of production space where it manufactures its components and assemblies, as well as other Hosokawa Group production facilities around the world. This has allowed the company to design and build well over 1.000 plants in Europe and overseas over the last 50 years. These plants lead to a rapid return on investment due to high performance, low maintenance requirements and minimised energy consumption.

The goal of Hosokawa Solids is to further expand the advantages of the solution, which is based on decades of broad experience in every bulk solids processing sector, in order to contribute even more powerfully to the success of its customers.

Own engineering and manufacturing capacity as well as manufacturer direct service

- Approx. 65 engineers skilled in process engineering, apparatus engineering, automation, plant engineering and project management

- Production area: 7000 m²

- maximum unit weight: 10 t

- maximum piece size: 200 m³ silo in one piece

- Manufacturer direct service with engineering service, after-sales service, carrying out tests on an industrial scale in our testing facilities, development of problem-related solutions including process and apparatus engineering.

Member companies

solids system-technik, founded in 1969 in the Basque region of Spain, is active in project planning and construction of automatic bulk solids handling turnkey systems. Four years later, the company Solids Components MIGSA S.L. was founded, which manufactures the components range of Hosokawa Solids. Today, the two Spanish company-divisions jointly form Hosokawa Solids S.L. with over 50 years of experience in solids handling, equipment and processes.

Hosokawa Solids Solutions GmbH in Germany has been advising customers on the project planning and execution of automatic bulk solids systems since 1969. Since 1983, the company has been producing its own machinery and equipment at its site in Landsberg am Lech.

Facts about Hosokawa Solids

Turnover:

- approx. 30 million euros annually

Engineering capacity:

- Approximately 65 engineers and technicians skilled in process and components engineering, project management and on-site services. Design stations are equipped with 2D and 3D CAD systems.

Manufacturing capacity:

- 7000 m² production area

- maximum unit weight: 10 t

- maximum piece size: 200 m³ silo in one piece.

Competence:

We have executed well over 10,000 orders in Europe and overseas. Countless bulk solids have been tested in our facilities on an industrial scale. The knowledge we have gained from these tests and our completed plants ensures that we have all the necessary competence for designing and executing new installations.

Based on our core competencies Storage & Discharge, Pneumatic Conveying, Weighing & Dosing, and Automation, we can provide turnkey solutions for all industries: chemicals, paints, varnishes, plastics, rubber, food, beverages, animal feed, minerals, glass, ceramics, enamel, foundry, steel, energy, environment …

Production:

Our components and assemblies are predominantly manufactured in our group-owned production facilities Ongoing quality controls and functional acceptance tests ensure our high quality standard. Hosokawa Solids develops and creates its own software, adapted to the specific project and material requirements for dosing and weighing and pneumatic conveying technology. We design and build process control systems applying high performance programmable logic controllers and industrial graphics for process visualisation, documentation and data management.

Quality:

Hosokawa Solids maintains a quality assurance system with experienced specialists and works according to DIN/ISO 9000 ff.

Prestige:

Counted among the company’s references are the market leaders of the bulk solids producing and processing industries such as Bayer - Ciba-Geigy - Henkel - AKZO NOBEL - BASF - Kömmerling - Continental - Nestlé - Coca-Cola - Martini & Rossi - Dyckerhoff - Knauf - Saint Gobain - Rocca - Lladro - Sumicol - Sinter Stahl - MVV Energie.

Success & profitability:

Hosokawa Solids has designed and built well over 1000 systems in Europe and overseas. These installations lead to a rapid return on investment due to high performance, low maintenance requirements and minimised energy consumption.

Vision

The vision of company founder H. J. Linder and the managing directors is to further expand the advantages of the solution, which is based on decades of broad experience in every bulk solids processing sector. This is to be achieved by integrating the individual companies into the Hosokawa Micron Group, which in turn will enable Hosokawa Solids to contribute even more powerfully to the success of its customers.

Through the integration of individual competences

- Engineering capacity for process and equipment technology

- Engineering capacity for control, automation and data management

- High-quality in-house production of proven equipment and components

- Direct service "around the clock" by the manufacturer, including inspections, maintenance, repair and original spare parts

It is our goal to provide our customers with a rapid return on investment through high performance, low maintenance requirements, 100% availability between revisions and optimised energy consumption.