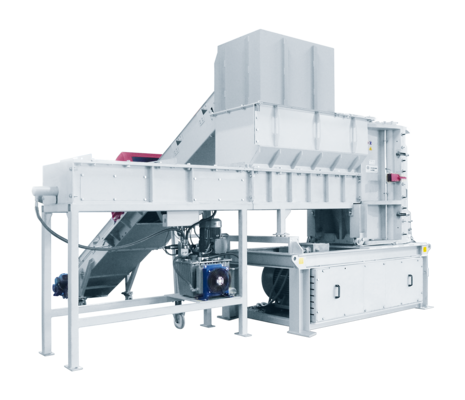

Le nouveau broyeur-déchiqueteur bien connu Polyplex d’Hosokawa Alpine est LA nouvelle solution pour le broyage des matières plastiques en tous genres !

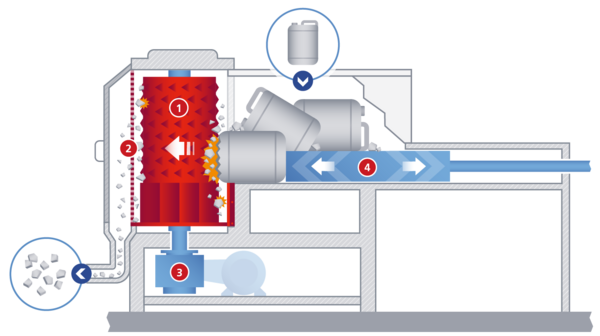

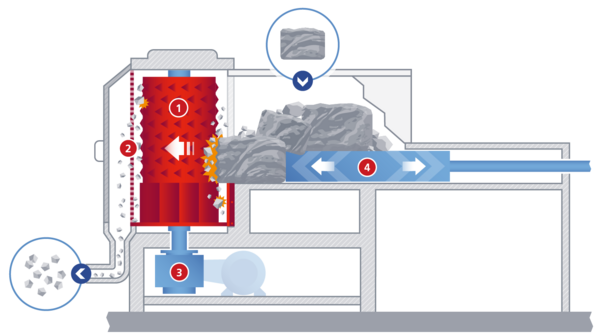

Vous gagnez de la place, du temps et des ressources ! Comment ? Le broyeur-déchiqueteur Alpine Polyplex PPC associe deux modes de fonctionnement dans un broyeur : un rotor de broyage disposé verticalement et un rotor de granulation.

Le concept de la machine a été adapté à vos besoins et positionné sur le marché sous la forme du Polyplex - à un prix avantageux. L’alimentation simultanée d’une grande variété de déchets plastiques représente un avantage considérable : le pré-tri et le dosage appartiennent désormais au passé !