L’un des grands défis de la préparation de milieux de culture cellulaire réside dans le nombre quasiment infini de formules comprenant de nombreux composants différents et diverses densités apparentes, tailles de particules ou fluidités. Cela nécessite un système universel qui englobe toutes les étapes du processus, de la formulation à l’emballage, en passant par le prémélange, le broyage et le post-mélange.

La technologie du groupe Hosokawa intervient immédiatement après la formulation et intègre les technologies clés de mélange et de broyage dans un processus homogène. Elle garantit ainsi un milieu de qualité supérieure.

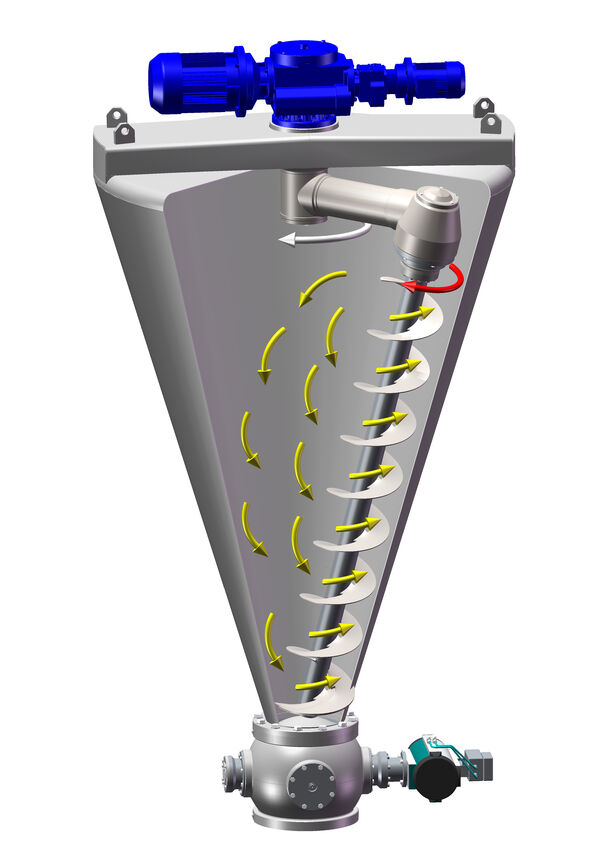

Dans le prémélangeur, les composants de la formule du milieu sont répartis de manière régulière, et ce mélange n’est pas séparé même pendant le dosage sur le broyeur. Dans le broyeur, les différents matériaux sont écrasés à une granulométrie uniforme et transportés directement dans un deuxième mélangeur. Ici, il est encore possible d’ajouter d’infimes proportions de mélange pour finaliser le produit. Ce mélangeur permet d’obtenir une remarquable homogénéisation de l’ensemble du lot et de la maintenir tout au long du processus d’emballage.

Ainsi, lors de la dernière étape, l’unité d’emballage exempte de contamination assure une qualité de produit uniforme du premier au dernier conteneur. Grâce à cette conception verticale de la disposition des machines, le guidage du produit est facile et l’effort de nettoyage est réduit. Comme aucun système de transport n’est nécessaire, l’équipement est également moins important.

Cette disposition des machines apporte en outre un rendement maximal des matériaux ainsi qu’un niveau élevé de flexibilité pour une multitude de formulations :

- Système inerte en circuit fermé (95 % d’économie d’azote)

- Broyage à température contrôlée (jusqu’à -40 °C)

- Haute précision de mélange

- Traitement en circuit fermé, de l’alimentation à l’emballage

- Nettoyage intégré

Les systèmes de préparation de cultures cellulaires doivent être flexibles et efficaces lorsqu’il s’agit de produire chaque jour de nouveaux lots aux formules différentes. Les possibilités de nettoyage jouent donc un rôle décisif dans la sélection de l’équipement de processus approprié.

Grâce au nettoyage automatisé des installations du groupe Hosokawa Micron, il est possible d’obtenir des résultats de nettoyage durables et reproductibles. Par ailleurs, les temps d’arrêt de l’installation sont réduits, tout comme les erreurs, qu’il s’agisse d’erreurs de manipulation ou de nettoyage. Par rapport au nettoyage manuel, cette forme de nettoyage d’installation est plus facile à planifier. Tout cela fait que l’utilisation des installations Hosokawa est économe en ressources, tant humaines que matérielles.

La conception verticale et aseptique présentant une qualité de surface exceptionnelle et les cuves de mélange coniques avec raccordement fixe au broyeur garantissent en outre une récupération maximale du produit.

Afin d’éliminer même les derniers résidus de produit du système, des buses de pulvérisation sont utilisées pour le nettoyage humide. Leur positionnement assure un nettoyage validé même aux endroits critiques. Après le nettoyage humide, tous les composants sont séchés à l’air chaud.

Une procédure automatisée permet de valider le nettoyage des installations.

Le facteur décisif est le traitement, du prémélange à l’emballage, dans un processus continu. Une approche intégrée de la solution de processus est essentielle. Elle empêche tout contact indésirable avec l’oxygène, l’humidité et les germes présents dans l’environnement. Des temps de traitement courts dans des conditions fraîches et conditionnées assurent la qualité des ingrédients. Un niveau élevé d’automatisation du processus, en particulier lors du nettoyage et du séchage, est source de sécurité et de flexibilité et permet de produire une très grande variété de milieux sur une seule installation, que ce soit par lots de quelques kilogrammes ou à l’échelle de la tonne.