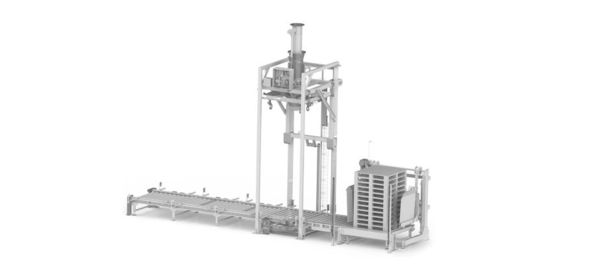

Filling devices

Simple, automatic filling and dosing of bulk materialsAfter processing, bulk materials need to be filled or transported for delivery to the customer, e.g. in silo vehicles, big bags/containers or barrels. Residual/waste materials also cannot be disposed of loose. That is why Hosokawa Solids Solutions offers a wide range of filling equipment, both for railway cars and lorries as well as for big bags, containers and barrels.

Filling is often combined with weighing and dosing. A main focus here is accuracy, i.e. recording the filled weight, reproducibility and dosing control. In combination with our weighing and dosing technology, high accuracy and reproducibility are possible. It can also be optionally calibrated as a SWA or SWE scale.

The filling process can be fully automated through a complete electrical and pneumatic installation, including integrated control.