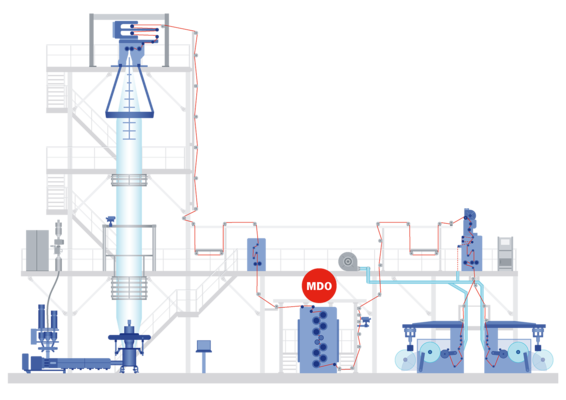

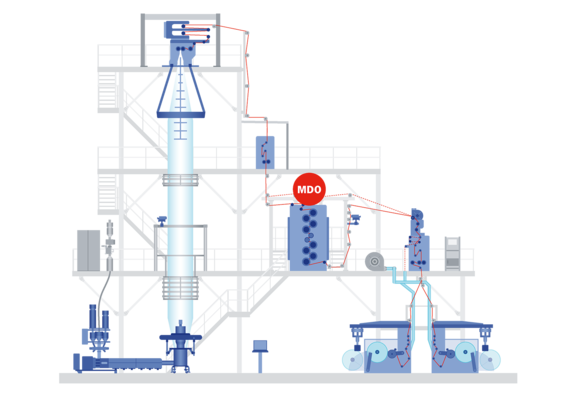

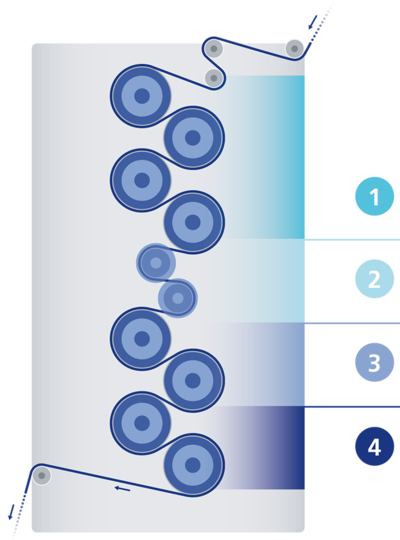

- Plus de 25 ans d’expérience dans l’étirage monoaxial – nous sommes les pionniers de la technologie MDO

- Technologie TRIO (Trim Reduction for Inline Orientation) unique pour des économies de matériau importantes lors du rognage des bords

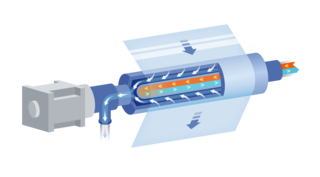

- Qualité de film MDO maximale avec une excellente aptitude au façonnage et une planéité optimisée, sans bords tombants ni pochage grâce à notre nouvelle technologie de vide

Obtenez des filmsbloqués et à double plat sur des lignes de soufflage de films Hosokawa Alpine. Contactez-nous, nos experts se feront une joie de vous conseiller !