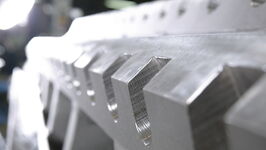

Cette gamme a presque déjà acquis un statut culte. Le concept ainsi que la conception lourde de la machine permettent l’utilisation de tout matériau sécable, en particulier lorsque des forces de coupe élevées sont requises et des débits importants doivent être gérés. Les classiques de la gamme de granulateurs ALPINE avec une technologie constamment améliorée.

- Puissance de 15 à 500 kW

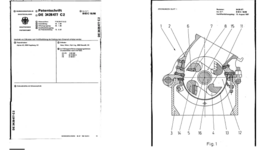

- Rotor de coupe à cisaillement croisé breveté

- Construction robuste en fonte sphéroïdale

- Capacité de coupe spécifique élevée pour des débits maximum

- Conceptions spéciales (structure et matériaux) disponibles

- Réception optimale des matériaux