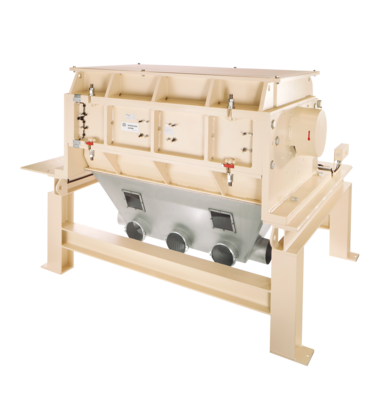

Ils incluent un rotor de coupe à cisaillement croisé breveté pour broyer les matières plastiques, articles en caoutchouc et produits de l’industrie agro-alimentaire.

- Couteaux de rotor divisés en couteaux unitaires courts

- Panier de tamis rabattable pour faciliter le nettoyage, le remplacement des couteaux et le réglage du jeu de coupe