Le Sugarplex est LE concept d'installation - spécialement conçu pour l'industrie sucrière. La machine a été développée de manière conséquente pour répondre aux besoins de l'industrie alimentaire.

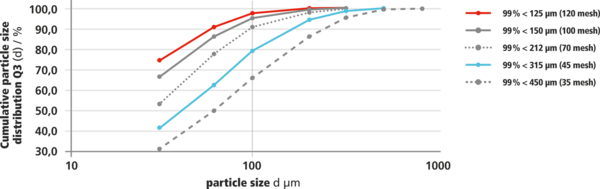

-

Nettoyage facile grâce à une porte du broyeur qui s’ouvre en grand

-

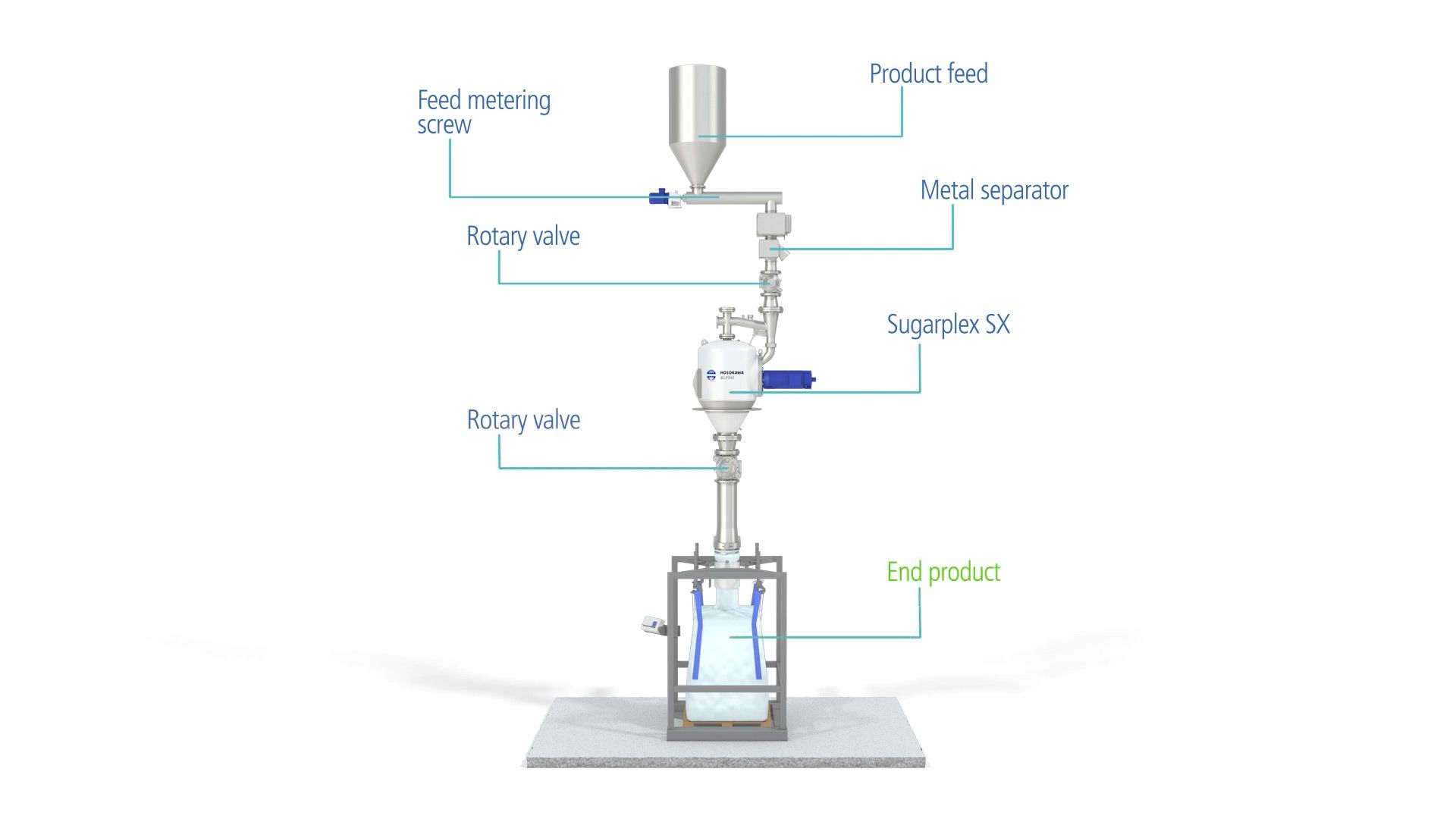

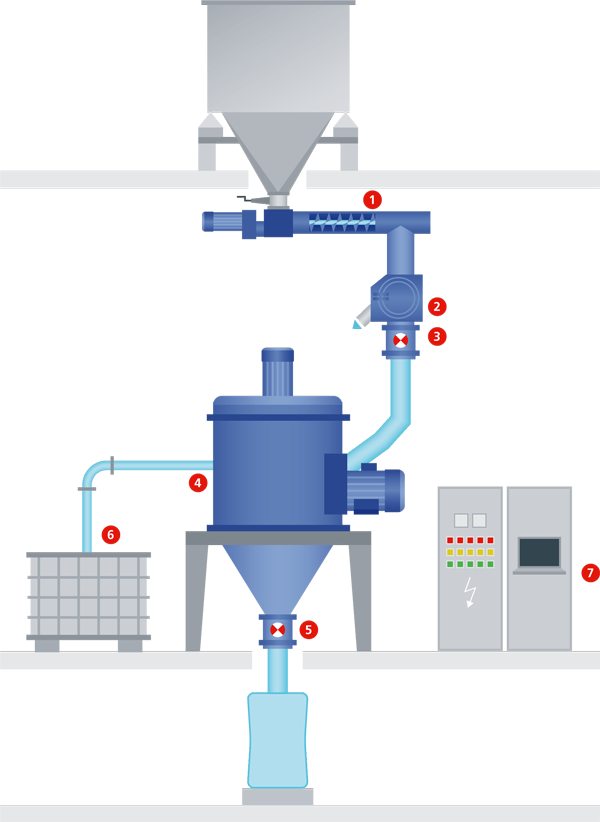

Installation compacte et peu encombrante

-

Une faible consommation d'énergie et des coûts d'entretien minimums promettent un retour sur investissement rapide (ROI)

Broyeur à impact fin avec disques à broches - intégré dans un récipient en acier inoxydable résistant aux chocs de pression