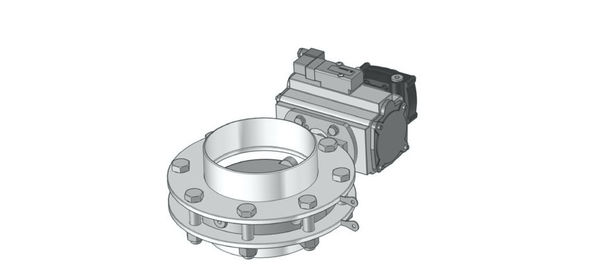

Locking valves for bulk solids

Securely lock conveying lines and containers, even with overpressure and vacuum applications.Product flows have to be interrupted on a regular basis in everyday life. Be it for maintenance work, at the end of a batch or in the event of a malfunction. In order to securely lock pipes and containers despite the variety of materials and operating conditions, Hosokawa Solids Solutions offers different locking valves in a variety of designs. These can be operated manually or automatically. Variants for pressureless downpipes/containers, vacuum applications or overpressure are also available.

The task could be, for example: Pressure-resistant, dustproof and reliable shut-off of

- abrasive or poorly flowing bulk solids

- at temperatures up to 250°C

- with high availability due to long seal service life and low-maintenance operation

- space saving design

- preventing any escape of product or gases to the outside

Shut-off valves for bulk solids with operating pressures above 0.5 bar comply with the Pressure Equipment Directive 2014/68/EU.

Typical examples of bulk material shut-off devices:

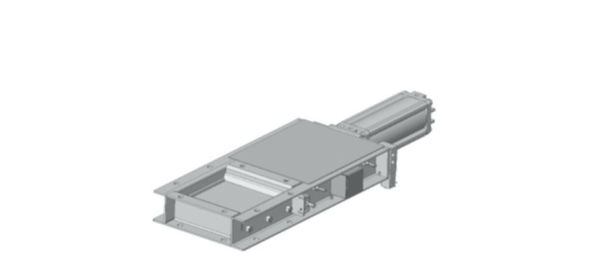

- Slide gate valve

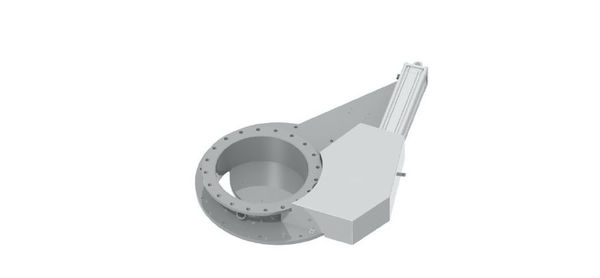

- Rotary gate valve

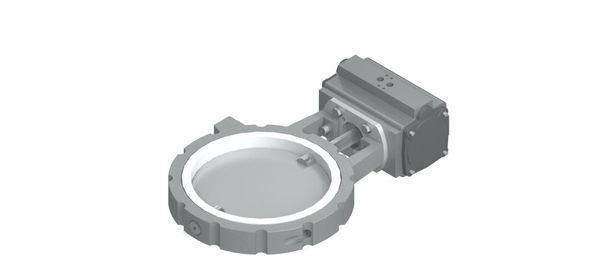

- Butterfly valve

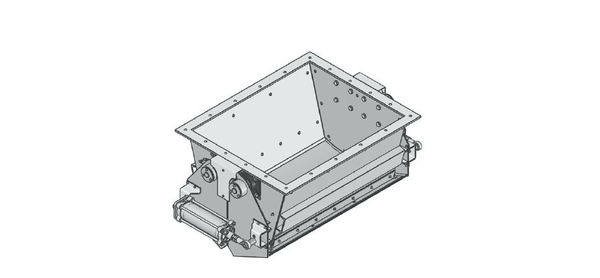

- Chambered airlocks

- Segmented shut-off devices

Hosokawa Solids Product Range

Locking valves- Dust Tight Slide Gates: Dustproof and pressure-resistant shut-off of bulk materials, with pneumatic hollow sectioning sealing, made to measure.

- Chamber valve, DSP type: Discharge and dosing from a pressure/vacuum system or injection e.g. into a reactor, filling and emptying discontinuously, barrier for gases or vapours.