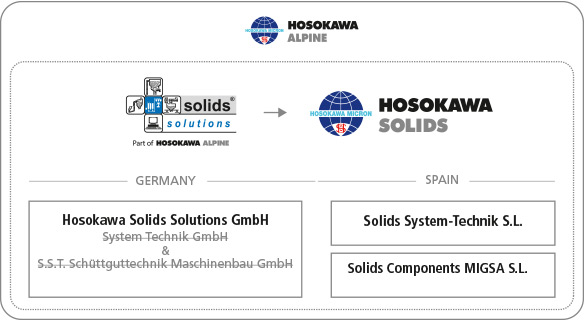

Hosokawa Solids Solutions GmbH

Your bulk solids. Our solution.Hosokawa Solids Solutions GmbH was founded in 1969 by H. J. Linder and is active in the project planning and execution of automatic bulk solids systems. The company develops and produces its own machines and components for handling bulk materials at its site in Schwabmünchen and with a subsidiary in the Spanish Basque Country. Its portfolio also includes special designs, after-sales service, inspections, maintenance and repair.

The core competencies of Hosokawa Solids are the technologies of storage & discharge, pneumatic conveying, weighing & dosing as well as automation. Based on these competencies, the company offers special industry solutions for chemicals, food & beverages, minerals, plastics & rubber, animal feed, energy and the environment.

Contact details Solids Solutions

Hosokawa Solids Solutions GmbH

Robert-Bosch-Str. 8

86830 Schwabmünchen, Deutschland

Tel: (+49) 8191/3359-0

Fax: (+49) 8191/3359-22

E-Mail: info(at)solids.hosokawa.com